First successful combustion test of N-2 motor (full grain)

One week to go until launch. Today was the first successful full-grain test of the N-2 motor. The modifications made to the final single-grain motor included changing the nozzle and combustion chamber from aluminum to mild steel and deepening the grooves in the snap ring. Arriving at the rugby field where we usually conduct our tests around 3:30 p.m., we found a group of new students visiting the site. Today’s test piece was a full-grain solid-state motor to be installed on the N-2 rocket, which had been postponed from last Friday’s test due to an ignition system failure. Again, the test motor that has been successfully tested so far is a test motor that outputs only half of the thrust required for the N-2 rocket manufactured for verification purposes, and the final product, the N-2 motor (i.e., full grain), has never been successfully confirmed in a static test.

Below is a video of the static test. Countdown! 10, 9, 8,…, it has ignited at 7 but the nozzle and bulkhead did not eject as before, nor did the side walls of the combustion chamber. The combustion is complete without melting. A memorable first successful combustion test for an N-2 motor!

The following video is an extract of the combustion section. It shows gas leaking from the gap between the nozzle and combustion chamber; a malfunction of the O-ring was suspected, but according to the student, he was able to visually confirm that the side wall of the combustion chamber had slightly expanded before today’s static test. It is not known at this time whether the deformation was caused by the load during processing or by heating from previous static tests, but we will verify this in the next combustion test. In addition, the connection between the nozzle and combustion chamber, where the heat flux is at its maximum, is red hot. We will measure this area with a thermography in the next round of testing to analyze and evaluate the strength loss due to heating.

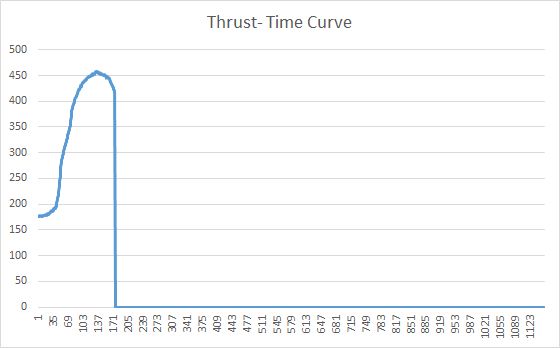

The thrust curve sent by the student at night is shown below. One unfortunate note is that the offset value at zero time, 170[N], occurred, so the measured thrust of 460N could not be justified. This will be an area for improvement next time.

The solid motors we tested were manufactured last Wednesday, so they are about 6 days old. Experience shows that the performance of our solid motors deteriorates with the passage of time after manufacture. Therefore, we decided to conduct a combustion test this Friday using a motor that was manufactured immediately after (i.e. 2 days old).