Preparation for launch of N-3 rocket

The last article was about the launch of the N-2 rocket. Now I’m talking about the preparations for launching its successor, the N-3 rocket. It feels like a year has passed at warp speed.

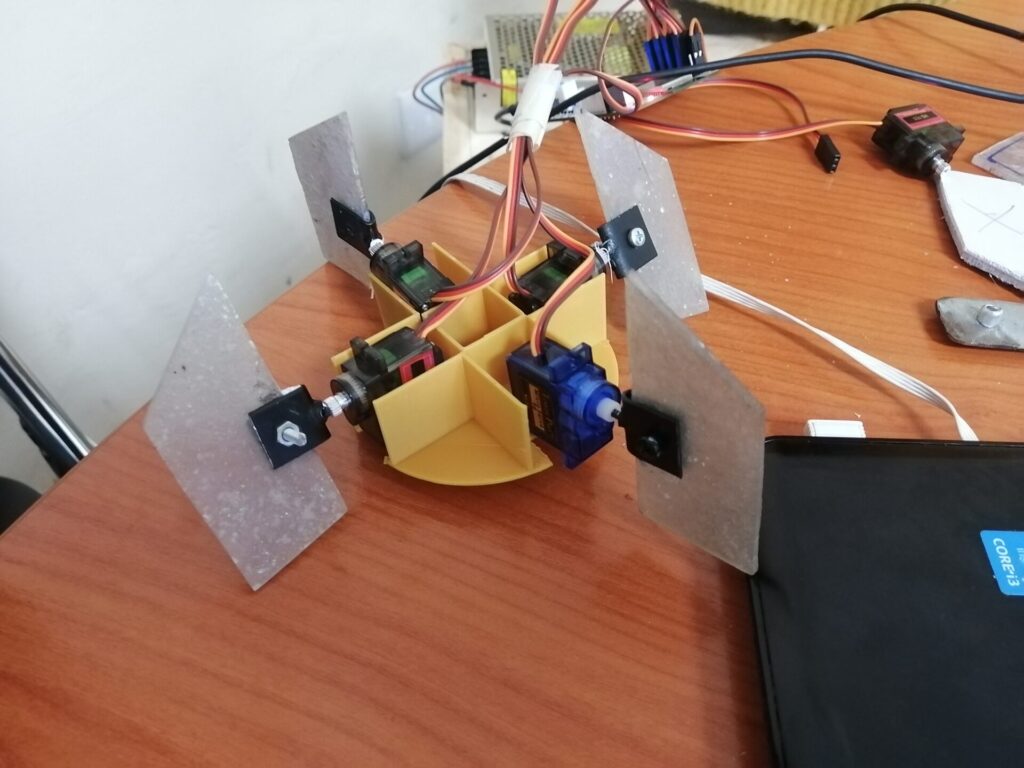

The outline of the N-3 rocket is as follows. First, the target altitude is increased from 500 m to 2,000 m. The total length of the fuselage is 180 cm, and the diameter of the fuselage is 80 mm. The two types of materials were used for the fuselage: a fiberglass and an aluminum. The N-3 rocket has been redesigned to be more powerful in many ways. The N-3 rocket is taller than me, giving the impression that our rocket has grown far.

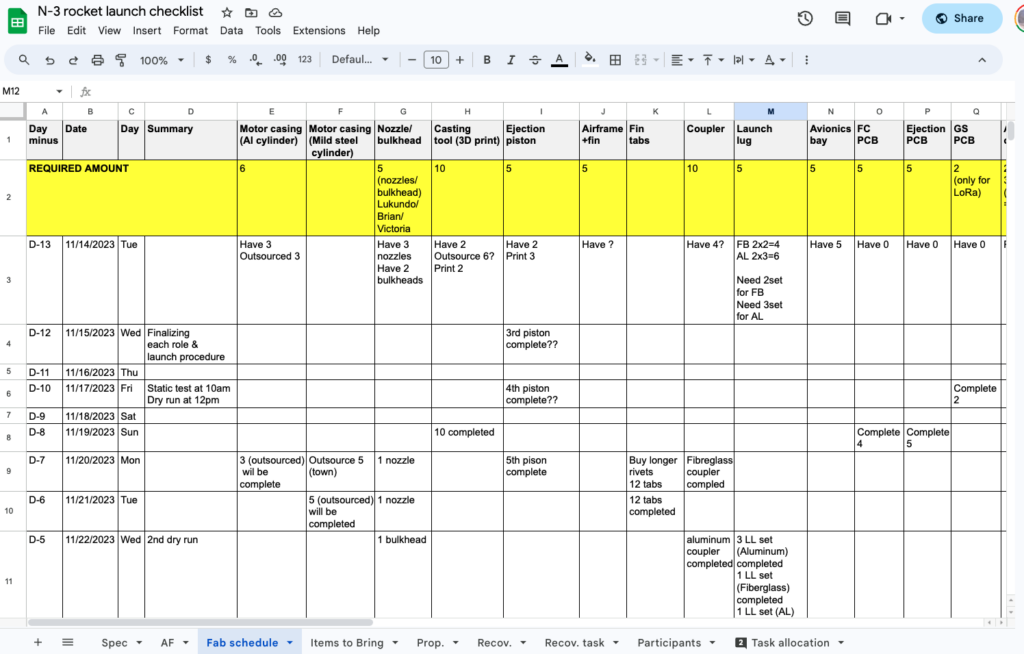

Later this month, we will launch five N-3 rockets named Simba, Chui, Kifaru, Tembo, and Nyati, in reference to Kenya’s BIG 5 animals. Although we started to prepare early, it is not easy to manufacture five rockets. We are preparing the components based on a manufacturing chart by considering what will be ready by what date. We are now digesting the tasks every day.

Especially time-consuming are 3D printing and metalworking. During this time of year in Kenya, it rains every day, and the 3D printing is frequently interrupted due to power outages. The 3D printer at home is in full operation almost around the clock. Since the 3D printer at the university also has a waiting list of students who are making their graduation projects, I outsourced a few parts to a local 3D printing service. The owner of the company told me that he is a graduate of JKUAT and attended a one-week digital fabrication course I offered on campus five years ago. After graduation, he started his own company related to electronic components. It is my pleasure to know that I was able to make a difference in the life of a young Kenyan.

The metal fabrication is also a lot of work: the solid rocket motor casing, bulkhead, and nozzle. The casing is 500 mm long, so boring the casing on a lathe takes time. Since it would be too time-consuming to manufacture all the parts by the students, I went to a fabricator in Nairobi introduced by one of our Nakuja alumnus.

The solid rocket motor casing was switched to mild steel after a static test. Similar to the N-2 rocket, it was revealed the aluminum casing would not hold up to the heat. The next generation N-4 is also expected to have no choice but to utilize mild steel for the casing.

We prepared an antenna stand for this launch. This is because we made the mistake of forgetting to place the antenna on the ground during the launch of the N-2 rocket.

In the previous launch, it took time to prepare each rocket on site since we didn’t rehearse the process in advance. Based on this reflection, a rehearsal (dry run) was held to confirm the roles of each person and the preparation flow.

The students start working in the afternoon once they finish their classes in the morning. Every day seems like a carnival as the entire team working together everywhere. The marathon continues with just a few more days left before the main event next week.

Launch N-2 rocket

The day has come. We finally launched the N-2 rocket we developed.

Preparations continued until late the night before the launch day. It was already past 8 PM when the team left the building.

This time three rockets were launched as the N-2 rocket family. They are named Tana, Galana, and Perkerra, respectively. These were named after rivers in Kenya.

The following are some of the positive aspects of this launch.

- Worked with KSA to launch three N-2 rockets

- The solid rocket motors worked well. It was especially good to discover a technique for bending the edge of the combustion chamber with a hammer in the field.

- Telemetry allowed us to downlink sensor data and camera images to the ground station

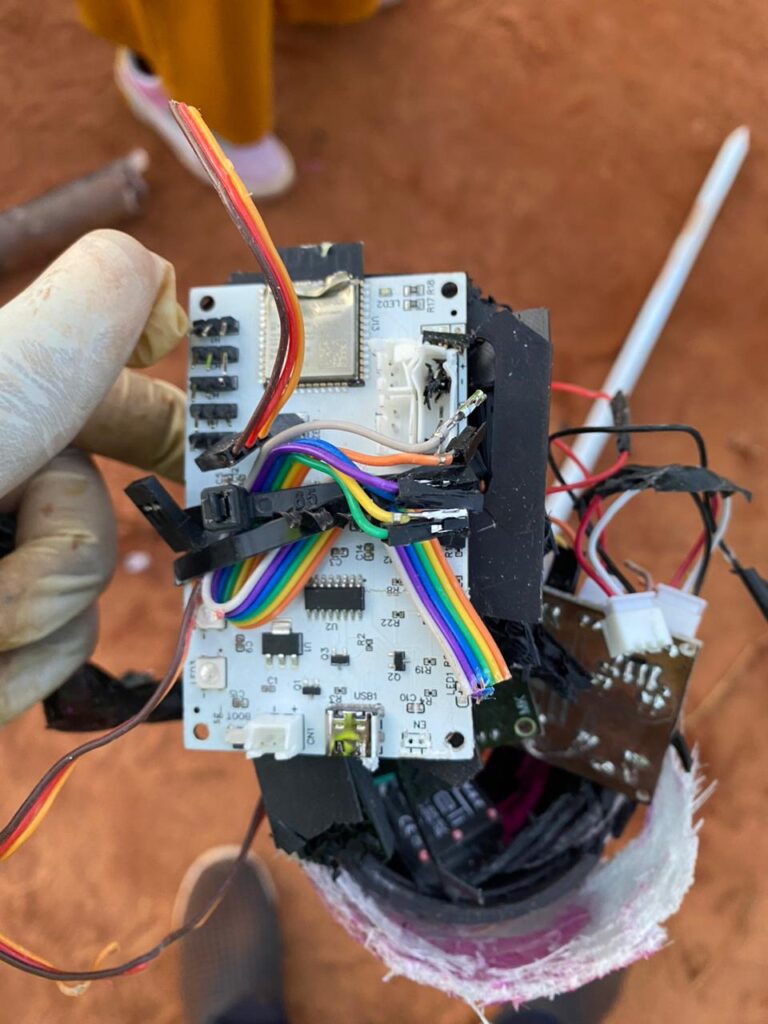

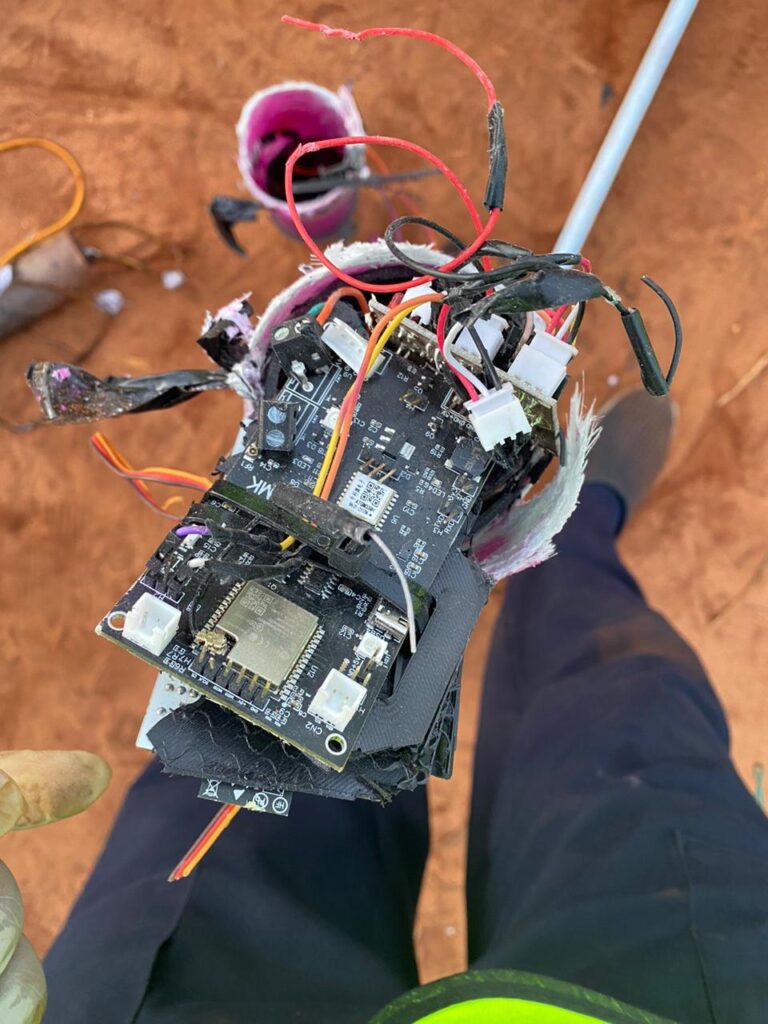

- ESP32 reset problem was encountered in the field, but was troubleshooted by the avionics team

- Pyrotechnic (crimson powder) worked and the parachute was released

- Launch sequence was created and the team complied with it

- Perkerra flew stable and achieved maximum apogee among three rockets

- Airframe accommodated all the subsystems without failure

On the other hand, areas for improvement are as follows

- Management issue

- Development timeline

- Avoid last minute work

- Technical issue

- Recovery system must be seriously prioritized

- Entire rocket subsystems have to be redesigned for smooth assembly

- Add internal memory to store the logging data

- Launch pad needs to be paid attention as it is crucial

We had a post-flight meeting to discuss the way forward.

The internship which will begin next January will focus on improving organizational issues as a top priority.

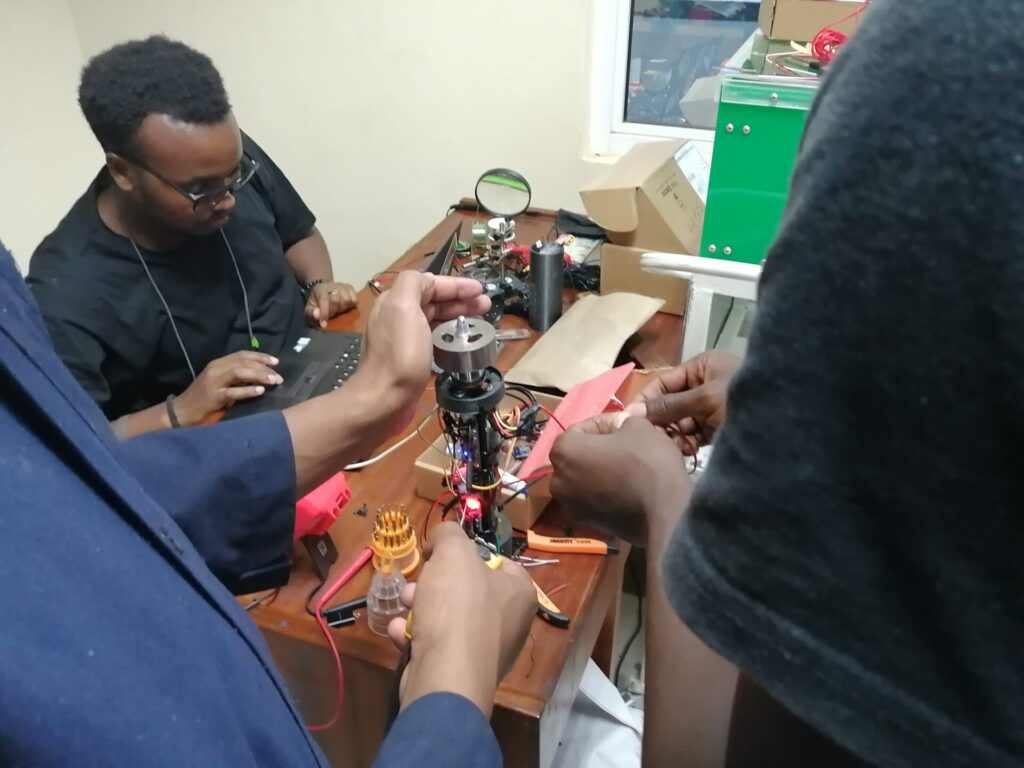

Testing flight computer using drone

Today, the avionics team conducted tests on the flight computer using a drone. The first test was to confirm the operation of the state machine. The flight computer of the N-2 rocket has a mechanism that detects and transitions between five states: initial state, ascent phase, apogee, descent phase, and landing phase.

The operation of the state machine was successfully verified. The next step is the long-distance communication test. We confirm that the sensor and camera videos are transmitted via Wifi without any problems.

The test was a success, as sensor values and camera video were received up to 500 m, as expected by the N-2 rocket.

First successful combustion test of N-2 motor (full grain)

One week to go until launch. Today was the first successful full-grain test of the N-2 motor. The modifications made to the final single-grain motor included changing the nozzle and combustion chamber from aluminum to mild steel and deepening the grooves in the snap ring. Arriving at the rugby field where we usually conduct our tests around 3:30 p.m., we found a group of new students visiting the site. Today’s test piece was a full-grain solid-state motor to be installed on the N-2 rocket, which had been postponed from last Friday’s test due to an ignition system failure. Again, the test motor that has been successfully tested so far is a test motor that outputs only half of the thrust required for the N-2 rocket manufactured for verification purposes, and the final product, the N-2 motor (i.e., full grain), has never been successfully confirmed in a static test.

Below is a video of the static test. Countdown! 10, 9, 8,…, it has ignited at 7 but the nozzle and bulkhead did not eject as before, nor did the side walls of the combustion chamber. The combustion is complete without melting. A memorable first successful combustion test for an N-2 motor!

The following video is an extract of the combustion section. It shows gas leaking from the gap between the nozzle and combustion chamber; a malfunction of the O-ring was suspected, but according to the student, he was able to visually confirm that the side wall of the combustion chamber had slightly expanded before today’s static test. It is not known at this time whether the deformation was caused by the load during processing or by heating from previous static tests, but we will verify this in the next combustion test. In addition, the connection between the nozzle and combustion chamber, where the heat flux is at its maximum, is red hot. We will measure this area with a thermography in the next round of testing to analyze and evaluate the strength loss due to heating.

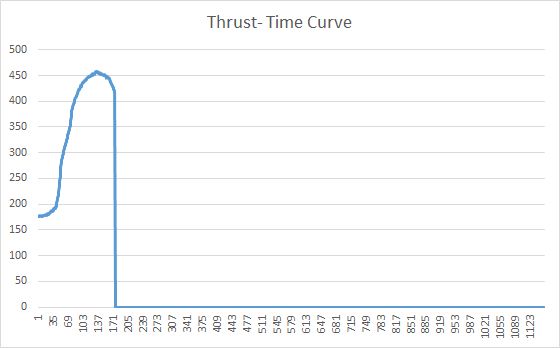

The thrust curve sent by the student at night is shown below. One unfortunate note is that the offset value at zero time, 170[N], occurred, so the measured thrust of 460N could not be justified. This will be an area for improvement next time.

The solid motors we tested were manufactured last Wednesday, so they are about 6 days old. Experience shows that the performance of our solid motors deteriorates with the passage of time after manufacture. Therefore, we decided to conduct a combustion test this Friday using a motor that was manufactured immediately after (i.e. 2 days old).

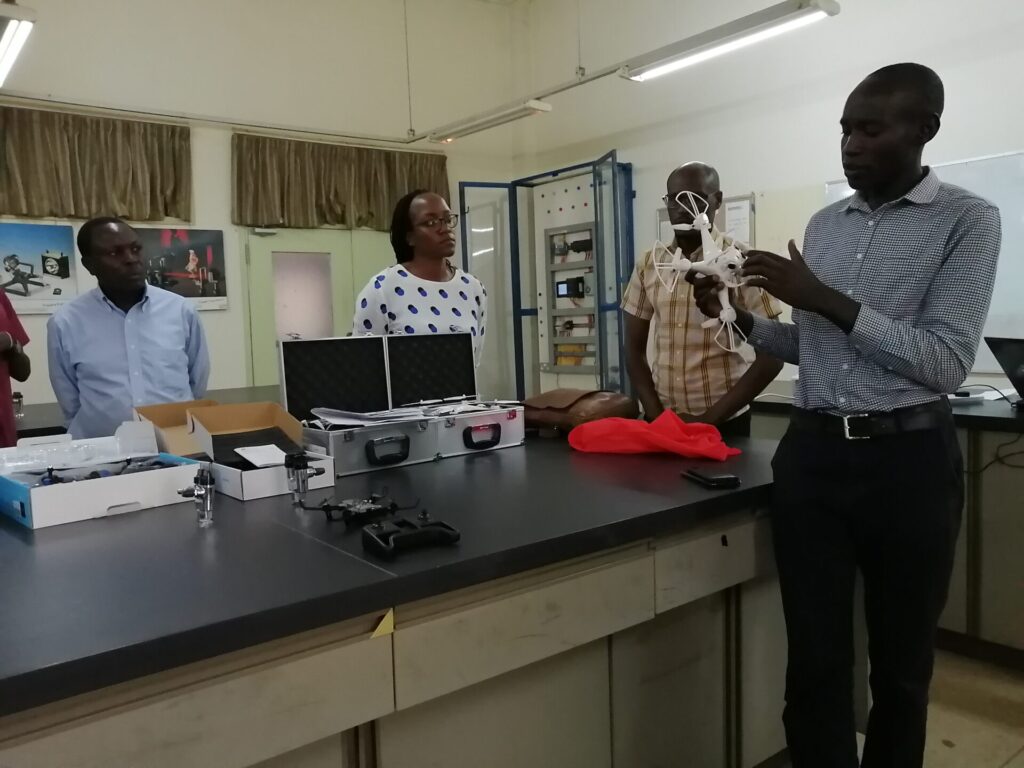

Tour of the Physics Department’s drone equipment

I visited the laboratory of the Department of Physics with members of the Drone Research Group (website: Drone Research Group at JKUAT). The chair of the Physics Department, who is a member of the drone group, suggested that they show us the drone equipment that the Physics Department owns. This equipment was donated to JKUAT in 2021 by GRSS (Geoscience and Remote Sensing Society), a part of IEEE. (Reference: Varsity Receives Drones from American based Engineers’ Society to aid Research)

As to why drone equipment was provided to the Physics Department, it has to do with the course offerings in JKUAT’s Physics Department.

- Control and instrumentation

- Renewable energy

- Geophysics

- Physics

In course 1, the research deals with scientific observations using laboratory-made electronic circuits, and previously used high-altitude balloons and Cansat. The use of a new drone will allow for a wider range of observations, and it was deemed appropriate to provide this to the department.

When I first heard about “instrumentation and control”, I wondered why this course is under the Department of Physics. I understand that it is positioned under the School and Pure and Applied Science in terms of designing and implementing electronic circuits for scientific observation and acquiring data. There still seems to be a graduation project where students try to implement a PLC (Programmable Logic Controller) system, which I assume this is rather a field of electronic engineering, by the way. In the Renewable energy field (2), for example, students are working on fluid flow simulations around wind turbines. And the geophysics such as the gravity survey for geothermal power generation (3) sounds unique to Kenya, because about half of Kenya’s electricity is generated by geothermal power generation.